Analysis of flow characteristics in circular pipes

DOI:

https://doi.org/10.14295/bjs.v4i10.760Keywords:

flow, flow regime, Reynolds number, experimental studyAbstract

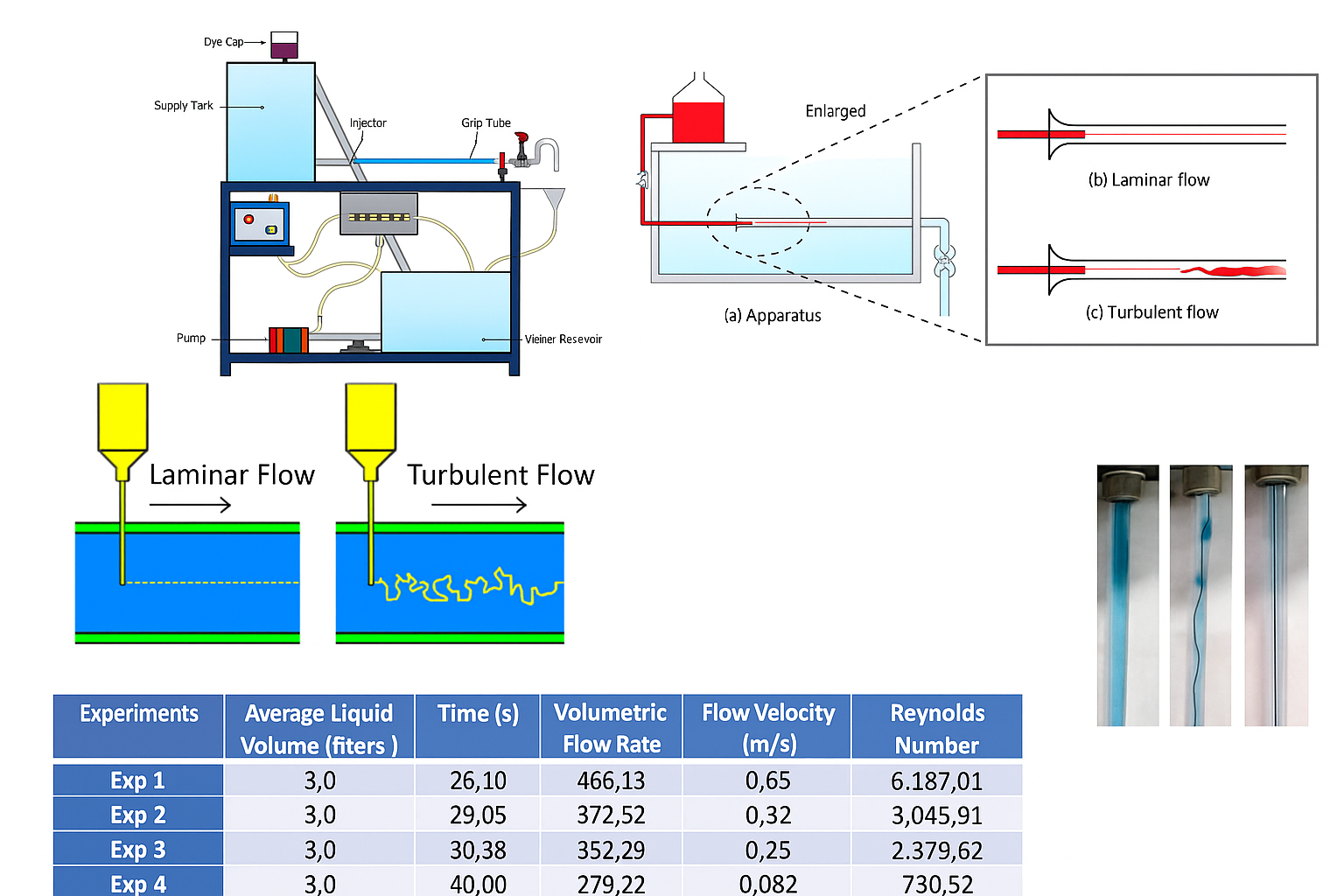

Determining the fluid flow regime is critical for optimizing oil production processes. To address this need, we evaluated a method for characterizing flow by calculating the Reynolds number. Experiments were conducted using a closed-loop piping system equipped with a flow meter and a visualization chamber. The flow rate was systematically increased, and all tests were performed in triplicate to ensure accuracy and reliability. The results showed that the experimental setup effectively distinguished laminar, transitional, and turbulent flows in both single-phase and multiphase systems, with transitions visually confirmed by observing streamlines. This study presents a validated and practical approach for accurately determining flow regimes, offering direct benefits for the design and operation of industrial flow systems.

References

Batchelor, G. K. (2000). An introduction to fluid dynamics. Cambridge University Press. DOI: https://doi.org/10.1017/CBO9780511800955

Bernard, P. S. (2009). On the laminar-turbulent transition of plane Couette flow: Part 1. The stability of low-amplitude perturbations to uniformly sheared flow. Journal of Fluid Mechanics, 627, 121-160.

Brennen, C. E. (2018). Fundamentals of multiphase flow. Cambridge University Press.

Çengel, Y. A., & Cimbala, J. M. (2007). Mecânica dos fluidos: Fundamentos e aplicações (1st ed.). McGraw-Hill.

Çengel, Y. A., & Cimbala, J. M. (2018). Fluid mechanics: Fundamentals and applications (5th ed.). McGraw-Hill Education.

Çengel, Y. A., & Cimbala, J. M. (2018). Fluid mechanics: Fundamentals and applications (4th ed.). McGraw-Hill Education.

de Araújo, E. M. G., Barros, E., & Barros, A. A. C. (2024). Characterization and analysis of gas-solid flow dynamics in fluidized bed systems. Journal of Chemical Engineering Research Updates, 11, 66-79. https://doi.org/10.15377/2409-983X.2024.11.4 DOI: https://doi.org/10.15377/2409-983X.2024.11.4

Fauci, L., & Gueron, S. (2006). A computational model of aquatic animal locomotion. Journal of Theoretical Biology, 241(4), 575-593.

Fauci, L. J., & Gueron, S. (2020). Biofluid dynamics: Blood flow and cardiovascular applications. Springer.

Fox, R. W., & McDonald, A. T. (2015). Introduction to fluid mechanics (8th ed.). Wiley.

Kim, J., Lee, J., & Lee, K. (2011). Turbulent flow and its applications in industrial systems. Springer.

Kim, J., et al. (2011). Active control of turbulence. Annual Review of Fluid Mechanics, 43, 133-162.

Kim, S., Lee, C., & Park, J. (2019). Turbulent flow dynamics and Reynolds number: Observations and applications. Journal of Turbulence, 26(1), 1-15.

Koschatzky, S., Felis, R., & Guzman, A. (2020). Stability of flow transitions in pipes: A computational and experimental study. Journal of Fluid Mechanics, 897, 15-32.

Leite, A. B., Bertoli, S. L., & Barros A. A. C. (2005). Absorção química de dióxido de nitrogênio (NO2). Engenharia Sanitária e Ambiental, 10, 49-57. https://doi.org/10.1590/S1413-41522005000100006. DOI: https://doi.org/10.1590/S1413-41522005000100006

Leite, A. B., Bertoli, S. L., & Barros, A. A. C. (2005). Processo de absorção de gases na minimização da poluição atmosférica. In: Conferência Apresentado no Congresso Regional, IV Región, 5, 23-25. Asunción, Paraguay.

López, D., Pérez, M., & García, F. (2020). Application of Reynolds number in industrial systems: Insights from fluid flow optimization. Industrial Fluid Mechanics, 34(2), 121-134.

López, J. M. (2015). Industrial applications of the Reynolds number: From pipe flows to aerodynamics. Annual Review of Fluid Mechanics, 47, 215-235.

Noriler, D., Meier, H. F., Barros, A. A. C., & Maciel, M. R. W. (2008). Thermal fluid dynamics analysis of gas–liquid flow on a distillation sieve tray. Chemical Engineering Journal, 136(2-3), 133-143. https://doi.org/10.1016/j.cej.2007.03.023 DOI: https://doi.org/10.1016/j.cej.2007.03.023

Oliveira, R. P., & Lopes, M. S. (2020). Transição de regimes de escoamento em sistemas industriais: Análise de parâmetros de escoamento. Journal of Fluid Dynamics, 28(4), 333-342.

Patankar, S. V. (2019). Numerical heat transfer and fluid flow. CRC Press. DOI: https://doi.org/10.1201/9781482234213

Pope, S. B. (2000). Turbulent flows. Cambridge University Press. DOI: https://doi.org/10.1017/CBO9780511840531

Schlichting, H., & Gersten, K. (2000). Boundary-layer theory (8th ed.). Springer. DOI: https://doi.org/10.1007/978-3-642-85829-1

Schlichting, H., & Gersten, K. (2017). Boundary-layer theory (9th ed.). Springer. DOI: https://doi.org/10.1007/978-3-662-52919-5

Silva, E. S. (2006). Estudo do escoamento bifásico em risers em movimento na produção marítima de petróleo em águas profundas. Master’s thesis, Faculdade de Engenharia Mecânica e Instituto de Geociências, UNICAMP.

Silva, F. S., Andrade, T. H. F., Lima, A. G. B., & Farias Neto, S. R. (2011). Estudo numérico do escoamento trifásico (água-óleo pesado-gás) tipo core-flow em uma conexão “T”. 6º Congresso Brasileiro de P&D em Petróleo e Gás – 6º PDPetro, Santa Catarina, UFSC.

Silva, J. L. (2011). Investigação do escoamento bifásico gás-líquido em uma coluna de bolhas retangular por meio da técnica CFD. Master’s thesis, Unicamp.

Silva, J. S. (2021). Escoamento multifásico: Fenômenos, modelagem e aplicações industriais. Revista Brasileira de Engenharia Química, 38(1), 55-67.

Silva, R. E. F. (2009). Implementação de um módulo de supervisão para um sistema de detecção de vazamentos em dutos de petróleo. Master’s thesis, UFRN.

Sreenivasan, K. R. (2018). An introduction to turbulence and its modeling. Cambridge University Press.

Smith, R. W., Johnson, M. E., & Miller, T. H. (2018). Effects of Reynolds number on fluid flow in microfluidic systems. Journal of Fluid Mechanics, 865, 42-61.

Soares, C., Noriler, D., Barros, A. A. C., Meier, H. F., & Wolf-Maciel, M. R. (2002). Computational fluid dynamics for simulation of a gas-liquid flow on a sieve plate: Model comparisons. Proceedings of the 634th Event of the European Federation of Chemical Engineering.

Soares, C., Noriler, D., Barros, A. A. C., Meier, H. F., & Wolf-Maciel, M. R. (2001). Numerical simulation of liquid flow on a distillation tray. In Iberian Latin American Congress On Computational Methods In Engineering and Brazilian Congress on Computational Mechanics. Campinas – São Paulo – Brasil.

Soares, C., Noriler, D., Wolf-Maciel, M. R., Barros, A. A. C., & Meier, H. F. (2008). Verification and validation in CFD for a free-surface gas-liquid flow in channels. Brazilian Journal of Chemical Engineering, 30, 323-325. https://doi.org/10.1590/S0104-66322013000200010 DOI: https://doi.org/10.1590/S0104-66322013000200010

White, F. M. (2016). Fluid mechanics (8th ed.). McGraw-Hill.

Zhou, L., Chen, Q., & Wang, F. (2022). Numerical simulation of complex fluid dynamics in multiphase flow systems. Computational Fluid Dynamics Journal, 39(5), 406-418.

Zhou, L., Zhang, Z., & Cheng, L. (2022). Recent advances in turbulence modeling for fluid flow in pipes and ducts. Elsevier.

Zhou, Y., et al. (2018). Advances in numerical simulations of fluid flow and heat transfer: A review of the state-of-the-art. International Journal of Heat and Mass Transfer, 123, 1254-1272.

Zhang, X., Li, S., & Wang, H. (2022). Enhanced heat transfer in turbulent flow: Recent developments and applications. Heat Transfer Engineering, 43(5), 234-247.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Eder Dias, Francisco Soki, Neusa Ramos, Vemba Sebastião, Geraldo Ramos, António André Chivanga Barros

This work is licensed under a Creative Commons Attribution 4.0 International License.

Authors who publish with this journal agree to the following terms:

1) Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgement of the work's authorship and initial publication in this journal.

2) Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgement of its initial publication in this journal.

3) Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work.